- Availability: 1

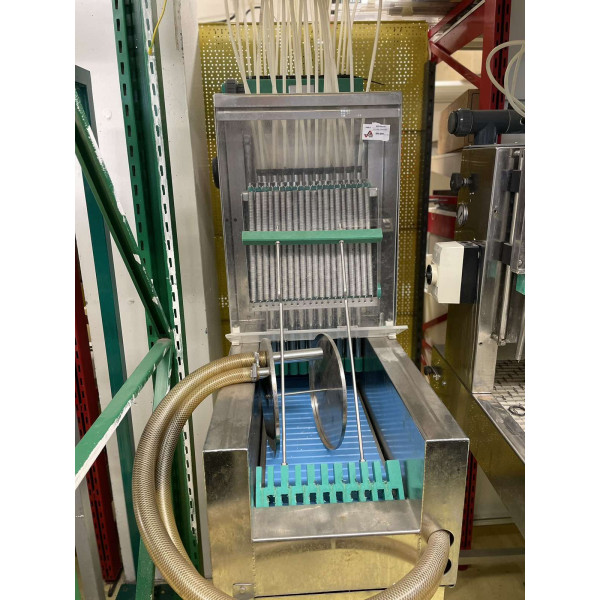

- Model: A488/3

Stainless steel design

30 cm wide ribbon

20 needles

External dimensions: 50x124x190 cm

380 V

All used products can be tried on at our premises, even with imported materials.

Consultation is required before the test.

If you have any questions about the product, please contact us at one of our contacts.

Briefly about quick pickling:

With the help of multi-needle pickling, the speed of salt penetration is increased (by reducing the length of the migration path). As a result, the chance of the proliferation of unwanted microbes is much lower than in products marinated for a long time with dry salting or top pickling. The safety of a product marinated at a sufficiently low temperature with a marinade of suitable microbiological quality raw material is enhanced by heat treatment as a technological step after pickling. This heat treatment is sufficient to practically destroy the vegetative forms of pathogenic and spoilage bacteria. Despite this, this product - in contrast to dry salted country ham - can only be kept refrigerated without the risk of microbiological deterioration, because the water activity value of such a quick-marinated, heat-treated product is higher (av = around 0.97), so it would not be able to prevent microbiological deterioration at room temperature.

In addition to the factors already mentioned (raw material with a low germ count, low pickling temperature, appropriate salt concentration, heat treatment temperature and time), the shelf life of heat-treated, pickled products is also significantly affected by whether there is a possibility of post-contamination, or whether the heat treatment is already a closed, bacteria-friendly in an impermeable package. In the latter case — if the cooling is adequate — the product can be kept for several months, even half a year, without microbiological and sensory deterioration.

While the microflora of the brine is important for traditional, wet pickling products, both in a positive sense (nitrate breakdown, aroma formation) and in a negative sense (deterioration), in the case of fast pickling processes, the brine practically does not cause any microbiological problems. The reason for this is that the marinades used in quick pickling are freshly prepared and are usually used in full after preparation.