- Availability: 1

- Model: TL300

The semi-automatic traysealer TL 300-skin is the ideal solution for cost-effective and professional vacuum packaging in trays and trays and for entry into professional skin packaging. Designed for the daily production of small to medium sized batches in all areas, the TL 300-skin tray sealing machine is also ideal for packaging in trade or the laboratory.

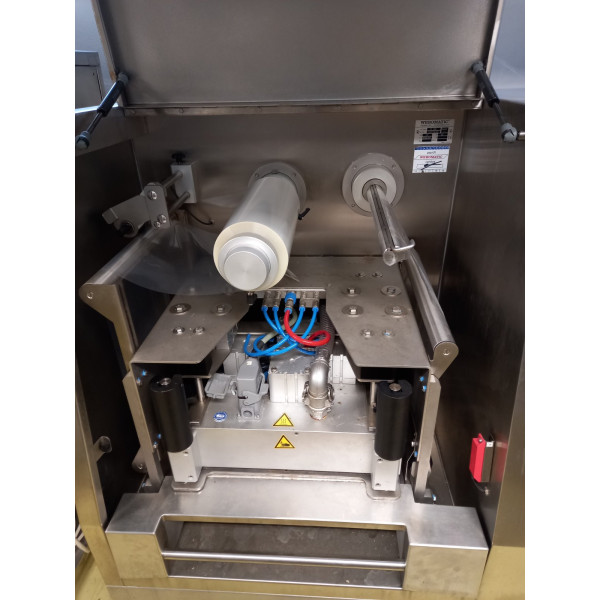

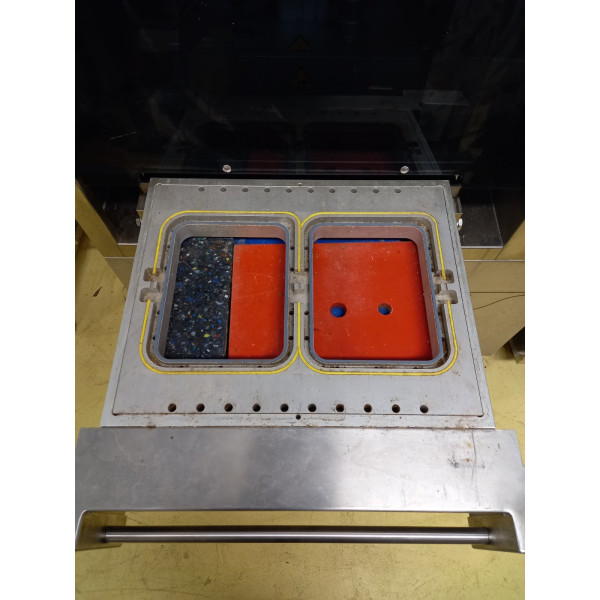

After placing the filled trays and closing the vacuum chamber, all processes are fully automated: evacuation, adding modified atmosphere (MAP), sealing and precise cutting of the trays.

The small semi-automatic tray sealers are the ideal solution for an inexpensive and professional vacuum packaging with trays and combine ease of use with reliability. They are ideally suited as an entry machine into tray packaging for smaller businesses or as an addition in larger productions or laboratories to cover samplings and new product launches.

The specially extended chamber allows for a variety of tray formats and tray arrangements – up to the size of ½ standard euro boxes and ½ standard gastronorm (½ GN) containers (max. tray size 400 x 300 x 120 mm). To save even more time, the high level of serviceability ensures that the sealing die-sets and formats can be changed quickly and easily without any additional tools. Every time an arrangement is to be swapped, a guided step-by-step manual can be selected on the screen to ensure that every change is done correctly and efficiently. Additionally, the film changing is completed in mere seconds with the easy-to-remove bolt.

Vacuum: 55 m3 /h, 63 m3 /h, 100 m3/h integrated (other capacities , external, upon request)

Control system: Mitsubishi PLC FX with optional remote diagnosis

Capacity: approx. 2—7 cycles/min.

External dimensions (W-D-H): 995 x 795 x 1600 mm

Weight: approx. 375 kg

Film transport: fully automatic with fi lm remnant rewinding system

Top film width: max. 350 mm

Film reel diameter: max. 350 mm, on 3” core

Electric: 400 V, 3 ph., N, PE, 50 cy, special voltage and/or frequency available as an option

Capacity: approx. 3,5 kW

Compressed air: approx. 17 NL/cycle with constant 6 bar max. degree of humidity 7 g/m3